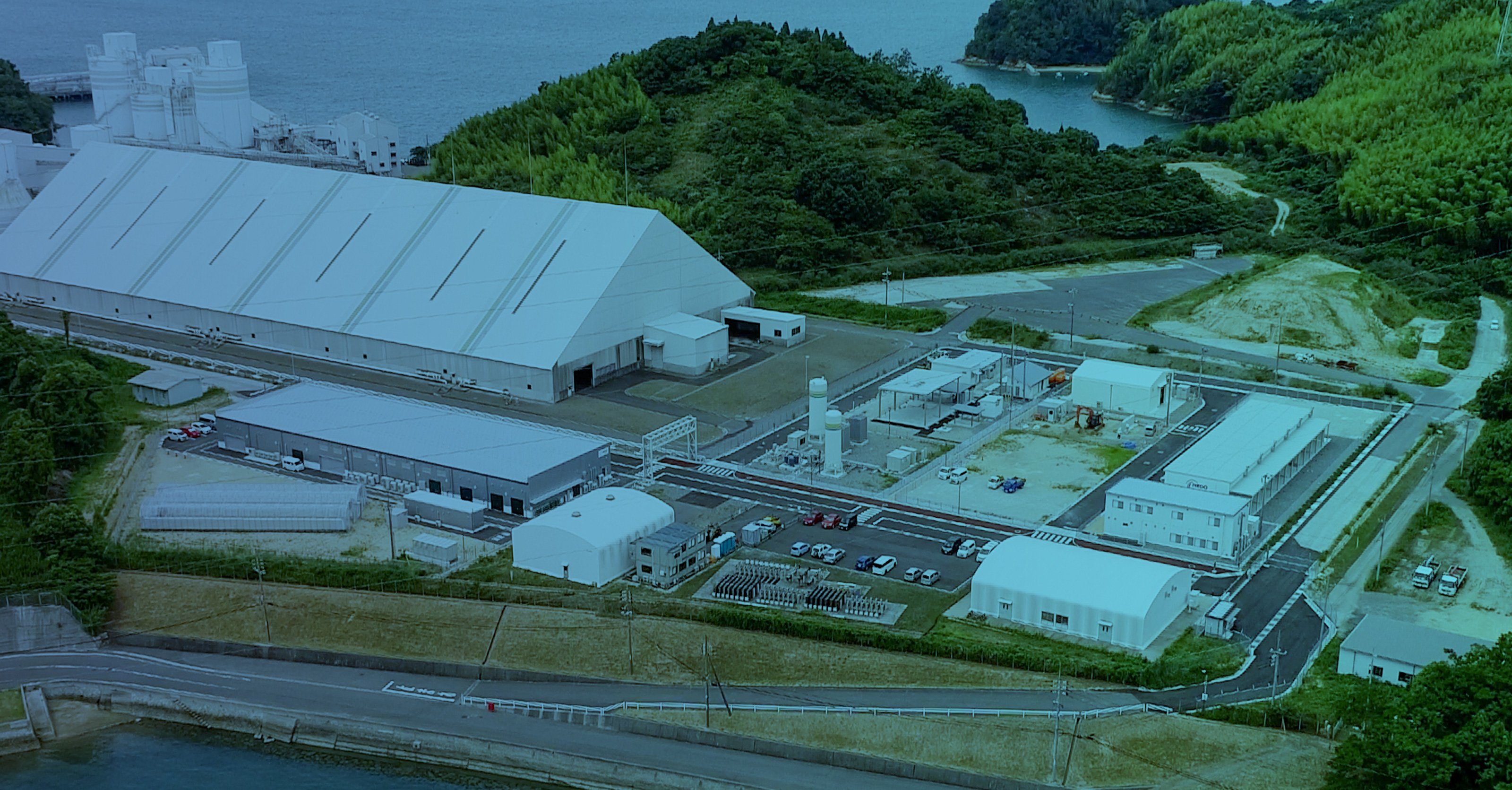

At Osaki-Kamijima Island, Hiroshima, located in the middle of the scenic Seto Inland Sea, a center of activity was established based on “Carbon Recycling 3C Initiative” announced by METI in 2019. This center offers companies and universities, aiming to realize a carbon-neutral and decarbonized society, hub of activity to promote their R&D activities. Our aim is to accelerate innovation and practical application of Carbon Recycling by conducting underlying technology development and demonstration in a concentrated and extensive manner.

Furthermore, through showcasing the details and results of their activities we will share Japan’s cutting-edge technologies to the world.