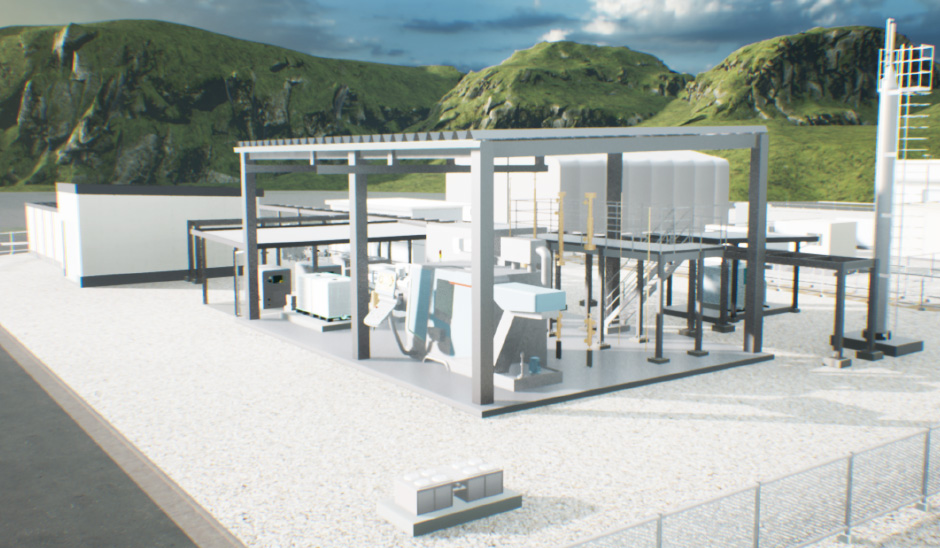

As soon as the center is ready, it will be open for tours for companies, research institutes, educational institutions, and other organizations that are working on the innovation and practical application of carbon recycling. Inquiries and consultations regarding tours are welcome. Please contact us using the inquiry form below.

Inquiry Form